|

| The initial step is to disassemble the wire armature. Cut all straps and cut on one side of the wire dinamonya. Remove / pull wire with pliers. |

|

| Preparation tools and materials to roll. Which is not visible on the photo are paper rope and duct tape. |

|

| Take a few pieces of wire former Dynamos who have been cut. Wrap the rollers as a benchmark mall / mall to large windings |

|

| Insert the wire into Kiren carefully assisted dg wood / bamboo / plastic or thin face who in the end to help push the wire into the hole Kiren |

|

| If all the wires are already entered into the hole Kiren. Close Kiren hole with bits of paper / plastic mica |

|

| Enter coils / windings second polar opposite direction. First pole appears in the image (left) direction counter clockwise windings. Being the second pole in a clockwise direction. |

|

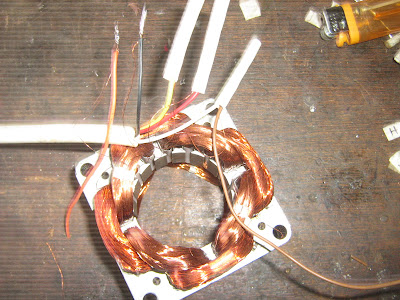

| These four main poles which have been incorporated into Kiren |

|

1 set coil starter which consisted of fruit loops @ 4 medium, low speed and starter. Tick on the base and the wire ends to facilitate the process of switching later

|

|

| 2 pieces of starter winding that is inserted into Kiren |

|

| Fourth winding starter who has entered then followed 2 windings medium speed |

|

| Primary winding and × Starter, medium, low speed which is ready. |

|

| The base and the tip of the wire which had been previously marked |

|

| The connection between the base and tip convolution medium / low speed and starter done in series. For more details, see "Schema I roll dynamo fan" |

|

| Peel the ends of the wire that has been spliced with a glimpse of the road burning with lighters ..., then connect the cable to the solder and then close the cable sheath degan |

|

| The next process is to do the binding in the cable and wire armature |

|

| Do coating with sirlak using small brushes evenly until absorbed into the winding |

|

| Coil was ready to test |

|

| Attach loops which have been prepared on the dynamo |

|

| When testing, do also testing on lap dynamo, if the rotation was weak .. check capacitor |

|

| Dinamo Telah siap dipasang dan digunakan |

Hopefully the picture above may be easier for you who are interested to learn to roll dynamo. Roll dynamo fan is just the first step in the process of learning to roll another dynamo. If you succeed ..., roll another dynamo preponderance or for the industry will be easier for you to understand.

Tidak ada komentar:

Posting Komentar